Once upon a time, in a world where humans toiled away in factories day in and day out, there came a revolutionary invention that changed the game forever: robots. These mechanical marvels, with their beeping buttons and whirring gears, have evolved over the years to become the unsung heroes of modern manufacturing. Join us as we take a journey through the fascinating evolution of robotics in the world of manufacturing, from clunky machines to sleek, sophisticated automatons that can do everything from assembling cars to flipping burgers. Grab your safety goggles and get ready to witness the robotic revolution in all its mechanical glory! Automation in Manufacturing Processes”>

Automation in Manufacturing Processes”>

Emergence of Automation in Manufacturing Processes

Automation in manufacturing processes has been evolving rapidly, much like a toddler learning to walk. What used to be a simple assembly line is now a complex network of robots, sensors, and software working together harmoniously.

Imagine a world where machines outnumber humans on the factory floor, much like a robot flash mob taking over the dance floor. The precision and efficiency of these machines make us wonder if they are secretly plotting to overthrow us and take control of the manufacturing world.

With the emergence of automation, we see tasks that were once done by hand now being performed flawlessly by machines. It’s like watching a magic show where the rabbits are robots and the magician is a programmer typing away furiously in front of a computer screen.

As we enter the era of Industry 4.0, the possibilities of automation in manufacturing processes are endless. It’s like a choose-your-own-adventure book where the only options are efficiency and productivity. The future is bright, my friends, and it’s all thanks to the rise of automation in manufacturing processes.

Artificial Intelligence on Society”>Robotic Arms in Assembly Lines”>

Artificial Intelligence on Society”>Robotic Arms in Assembly Lines”>

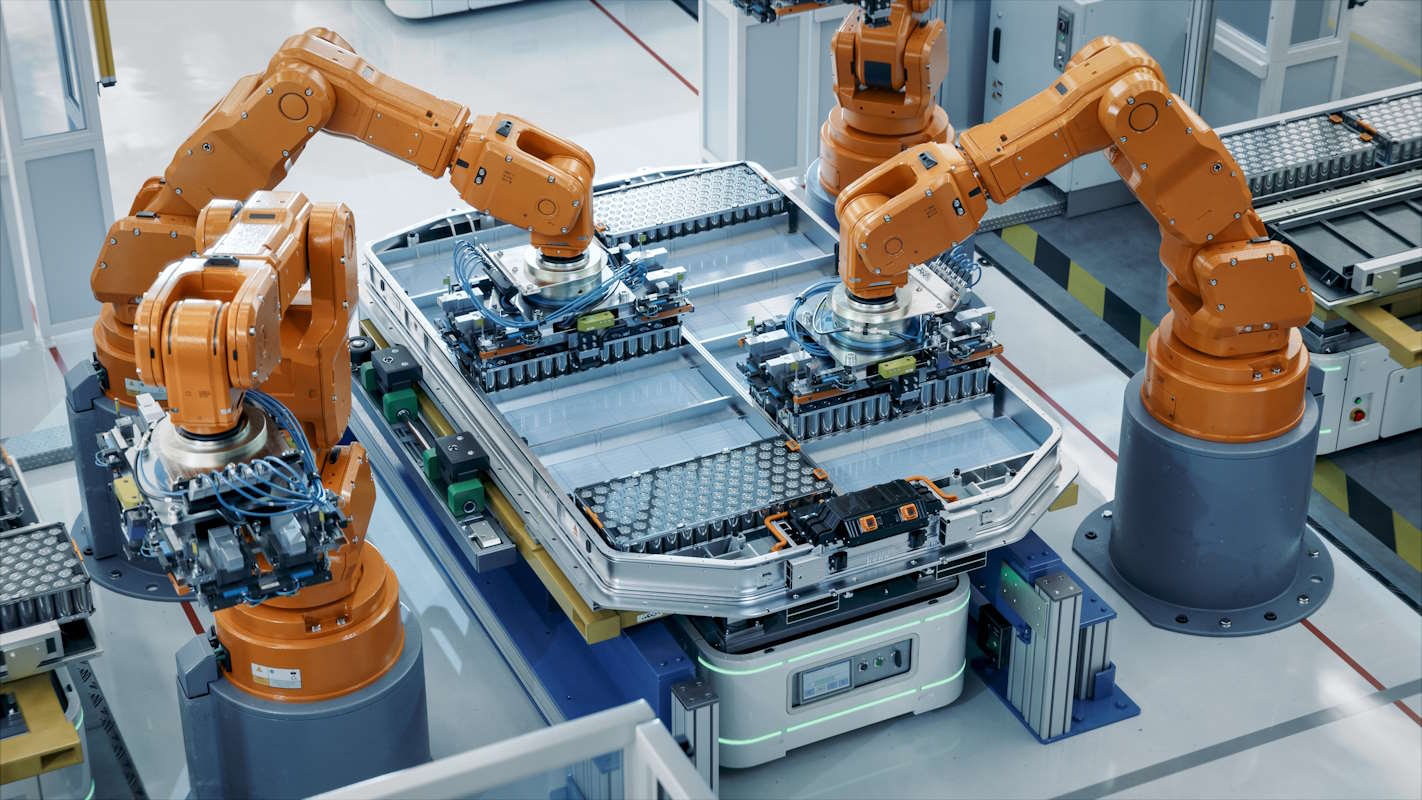

Introduction of Robotic Arms in Assembly Lines

Robotic arms have become the new celebrities in the manufacturing world, taking center stage on assembly lines across the globe. These mechanical wonders are like the rockstars of the manufacturing industry, effortlessly performing tasks with precision and speed that leave us mere mortals in awe.

Gone are the days of human workers toiling away on assembly lines, when all we could rely on were sore muscles and tired minds. Enter the robotic arm, with its sleek design and ability to work non-stop without a coffee break in sight. It’s like having the Energizer bunny as your coworker, but way cooler.

With the , the efficiency and productivity levels have soared to new heights. These robotic marvels can perform a myriad of tasks, from welding and painting to sorting and packaging, all without breaking a sweat. They are the ultimate multitaskers, making us humans look like amateurs in comparison.

In a world where time is money, robotic arms are the ultimate investment. They work tirelessly and accurately, helping companies meet deadlines and exceed expectations. So next time you see a robotic arm in action on an assembly line, give it a virtual high-five and thank it for making our lives easier.

Advancements in Sensor Technology for Enhanced Precision

Remember the days when sensors were as accurate as a blindfolded archer? Well, those days are long gone! Thanks to the incredible advancements in sensor technology, precision has reached new heights. No more guessing games or crossing your fingers and hoping for the best. Sensors are now like the Sherlock Holmes of the tech world – always on point and ready to solve the mystery of precise measurements.

One of the most exciting developments in sensor technology is the use of **machine learning** to enhance precision. These sensors are not only smart, they’re genius-level smart. They analyze data faster than a cheetah on an espresso binge and can provide measurements with pinpoint accuracy. It’s like having a mini Einstein in your pocket, ready to assist you in all your precision-related endeavors.

Another groundbreaking advancement is the **integration of artificial intelligence** into sensor technology. These sensors are not only precise, they’re intuitive. They can anticipate your needs before you even know you have them. It’s like having a personal assistant who can read your mind and provide you with accurate measurements without you even having to ask. Who needs a crystal ball when you have AI-powered sensors on your side?

And let’s not forget about the **miniaturization** of sensors. These tiny but mighty devices are like precision ninjas, able to sneak into the tightest of spaces and provide accurate measurements where larger sensors fear to tread. It’s like having a secret weapon in your toolbox, ready to unleash its precision powers whenever you need them. With sensors this small and precise, the possibilities are endless.

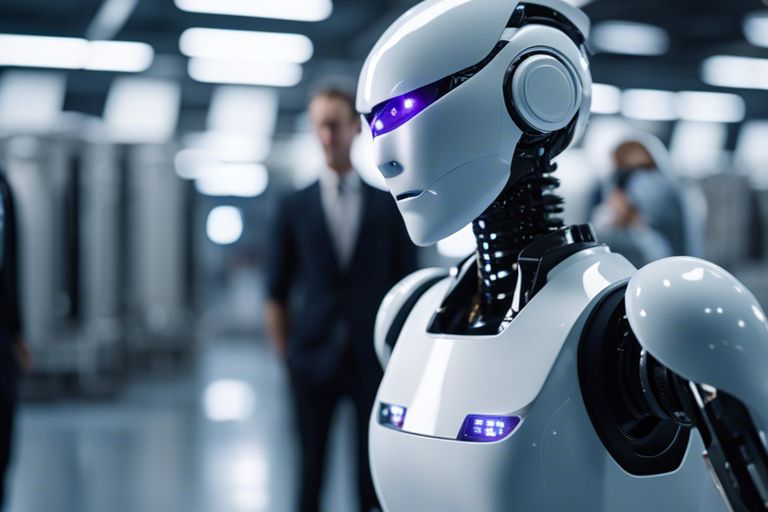

Integration of Artificial Intelligence in Robotics

Who knew the day would come when we would have robots running around with AI embedded in them? It’s like a sci-fi movie come to life, but without the killer robots trying to take over the world. Thanks to the , our mechanical friends are getting smarter and more efficient by the day.

Imagine a robot that can learn from its surroundings and adapt to new situations on the fly. With AI at the wheel, robots can now analyze data in real-time, make decisions based on that information, and even predict future outcomes. It’s like giving your Roomba a PhD in astrophysics – except it’s still just going to clean your floors.

From self-driving cars to surgical robots, the possibilities are endless when it comes to the marriage of AI and robotics. These intelligent machines can now perform complex tasks with a level of precision and accuracy that would make even the most skilled human worker jealous. It’s like having a team of tireless, super-intelligent minions at your beck and call – minus the evil overlord part.

Implementation of Collaborative Robots for Human-Robot Interaction

Fellow humans, the time has come for us to embrace our new robot overlords! But fear not, for these robots are not here to replace us, but to work alongside us in perfect harmony. The is upon us, and it’s going to be a game-changer.

Picture this: you’re working on a tedious task that requires hours of repetitive motion. Enter the collaborative robot, ready to assist you with its precision and efficiency. No more sore muscles or dull moments, thanks to our new mechanical friends!

With the introduction of collaborative robots, the possibilities are endless. From manufacturing to healthcare, these handy robots can lend a helping hand in so many industries. And the best part? They never call in sick or ask for a raise!

So let’s welcome our robotic companions with open arms and gears. Together, we can achieve greatness and revolutionize the way we work. The future is bright, my friends, and it’s filled with whirring motors and flashing lights. Embrace the collaboration, and let the robots lead us into a new era of innovation!

Development of Autonomous Mobile Robots for Material Handling

Are you tired of lugging around heavy boxes and materials all day? Well, fear not, because the future of material handling is here with the development of autonomous mobile robots! These robots are not your average co-workers – they are efficient, tireless, and always happy to help out with the heavy lifting.

With advanced sensors and algorithms, these robots are able to navigate through complex warehouse environments with ease. No need to worry about them bumping into walls or getting stuck – they are smart enough to find their way around obstacles and reach their destination without breaking a sweat (unlike some of us humans).

Imagine a world where you can simply input a list of items that need to be moved, sit back, and watch as these robots meticulously pick up each item and deliver them to their designated locations. It’s like having your own personal army of hard-working minions at your beck and call!

So say goodbye to backaches and sore muscles – the future of material handling is bright with these autonomous mobile robots leading the way. Embrace the revolution and let these robots take the heavy lifting off your shoulders (literally)!

Future Trends in Robotics for Manufacturing Industry

Robots in the manufacturing industry are no longer just giant metal arms mindlessly welding pieces together. They are becoming smarter, more versatile, and even capable of making decisions on their own. Here are some of the exciting future trends in robotics for manufacturing:

One trend we are seeing is the integration of artificial intelligence into robots. This means that robots will be able to learn from their mistakes, adapt to new situations, and even come up with creative solutions to problems. Imagine a robot on the assembly line that can troubleshoot issues on its own and make adjustments in real-time. It’s like having a mechanical genius on your team!

Another trend to look out for is the use of collaborative robots, or cobots. These are robots designed to work alongside humans, sharing tasks and complementing each other’s strengths. No longer will robots be confined to cages, separated from their human counterparts. Instead, they will be part of the team, high-fiving their human coworkers and cracking jokes during coffee breaks.

Lastly, the future of robotics in manufacturing will also see an increase in the use of 3D printing technology. Imagine a robot that can print components on demand, eliminating the need for expensive molds and tools. With 3D printing capabilities, robots will be able to create custom parts quickly and efficiently, revolutionizing the way products are made.

FAQs

How have robots in manufacturing evolved over time?

Well, back in the day, robots were basically just clunky metal arms that could maybe pick up a few things and do some basic tasks. But now, they’re like the Transformers of the manufacturing world – sleek, efficient, and highly specialized.

What are some of the key advancements in modern robotic technology?

Oh, where do I start? We’ve got robots that can see, robots that can learn, robots that can even collaborate with humans. It’s like we’re living in a sci-fi movie (but without the evil robot overlords…yet).

How have robots improved efficiency in manufacturing processes?

Imagine a world where robots don’t get tired, don’t take breaks, and never call in sick. That’s the kind of efficiency we’re talking about here. Robots can work around the clock, without ever complaining or asking for a raise.

Are there any drawbacks to relying heavily on robots in manufacturing?

Well, there’s always the risk of a robot uprising, but hey, as long as we treat our robot overlords with respect and maybe throw in the occasional oil change, we should be fine. In all seriousness, the main drawback is probably the initial cost of setting up a robotic workforce, but hey, you gotta spend money to make money, right?

What does the future hold for robotics in manufacturing?

Who knows? Maybe one day robots will be running the show and we’ll all be sipping margaritas on the beach while they do all the work. Or maybe they’ll conquer humanity and turn us all into their mindless robot slaves. Either way, it’s gonna be one heck of a ride!

—

Robots, Assemble!

And there you have it, the wild and wonderful world of modern robotics in manufacturing. From humble beginnings to advanced automation, these mechanical marvels have truly come a long way. So next time you see a robot diligently working away on the factory floor, just remember – it’s all thanks to the evolution of modern robotics. Now go forth and let the robots rule the assembly line!