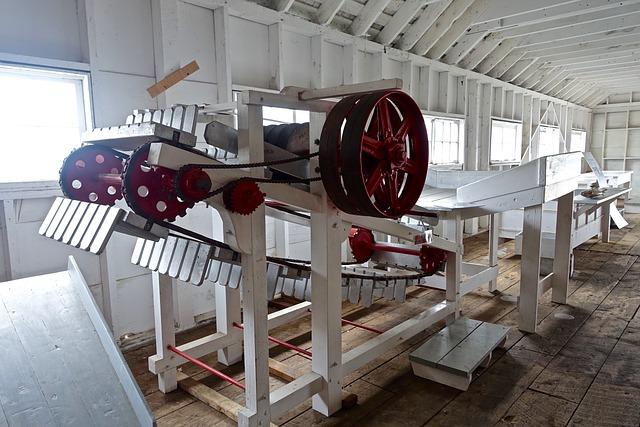

Welcome to the future, where machines are taking over the world – quite literally! In the manufacturing industry, robots are no longer just a sci-fi fantasy; they’re working alongside humans to revolutionize the way we make things. From assembly lines to 3D printing, automation is changing the game and giving traditional manufacturing methods a run for their money. So grab your hard hat and buckle up, because this article is about to take you on a wild ride through the futuristic world of automated manufacturing.

Benefits of Automation in Manufacturing

Picture this: a world where robots do all the dirty work in manufacturing, leaving you to kick back and relax with a cold beverage. Sounds like a dream come true, right? Well, automation in manufacturing is making that dream a reality. Here are some of the many benefits:

First and foremost, automation increases efficiency. Robots don’t need lunch breaks, they don’t get tired, and they definitely don’t waste time gossiping at the water cooler. With automation, your production line can run 24/7 without missing a beat.

Next up, quality control. Robots are precise, accurate, and never make mistakes (unless they’ve been programmed to…). This means fewer defects, less waste, and a better end product for your customers. Say goodbye to those pesky recalls and hello to glowing reviews!

And let’s not forget about safety. Robots can handle the dangerous, dirty, and dull tasks that no human wants to do. From lifting heavy objects to working in extreme temperatures, automation keeps your workers out of harm’s way. Plus, it’s a lot more fun to watch robots do all the heavy lifting while you sip on your coffee and cheer them on!

Increased Efficiency and Productivity

With the latest productivity tools and strategies available on the market, you’ll be amazed at how much more you can accomplish in a day. Say goodbye to wasting time on mundane tasks and hello to a more efficient workday!

Imagine being able to streamline your workflow with just a few clicks of a button. From project management software to automation tools, there’s a solution for every aspect of your workday that will help you achieve more in less time.

By harnessing the power of technology and implementing smart productivity hacks, you can finally break free from the shackles of inefficiency. No more staring blankly at your computer screen wondering where the time went – you’ll be powering through your to-do list like a productivity superhero!

So why wait? Take control of your workday and unleash your full potential with these game-changing productivity tools. Your future self will thank you for it!

Streamlined Production Processes

Have you ever felt like you’re stuck in a never-ending loop of inefficiency when it comes to production processes? Well, fear no more because we have the solution for you! Our will revolutionize the way you work, saving you time and energy.

Imagine a world where your workflow is as smooth as butter, where tasks are completed with ease and precision. With our system in place, you’ll be able to tackle any project with confidence and speed. Say goodbye to bottlenecks and hello to a new era of productivity!

Our involve the use of cutting-edge technology and innovative techniques to optimize your workflow. From automated scheduling to real-time collaboration, we’ve got you covered. Plus, our team of experts is always available to provide support and guidance whenever you need it.

So why wait? Join the revolution and transform your production processes today with our streamlined approach. You’ll wonder how you ever managed without it!

Cost Savings and Improved ROI

Who doesn’t love saving money and making more of it? We’ve got the tips and tricks to help you do just that with your business!

By implementing cost-saving measures, you can put more money back into your pocket and watch your ROI skyrocket. Check out these ideas:

- **Cutting unnecessary expenses:** Take a look at where your money is going and see if there are any areas where you can trim the fat. Do you really need that fancy coffee machine in the break room?

- **Outsourcing:** Sometimes it’s more cost-effective to outsource certain tasks rather than hiring in-house. Plus, you don’t have to deal with Susan from accounting’s weird nail-biting habit.

Improving your ROI doesn’t have to be rocket science. With a little creativity and some strategic thinking, you can see big returns on your investment. Here’s how:

- **Investing in marketing:** A killer marketing campaign can bring in a ton of new customers and boost your sales. Just make sure it doesn’t involve any questionable jingles that get stuck in people’s heads.

- **Streamlining processes:** Wasted time is wasted money. Find ways to make your business more efficient, whether it’s through automation, better organization, or getting rid of that ancient fax machine in the corner.

Enhanced Quality Control and Consistency

Here at our company, we take quality control very seriously (well, most of the time). Our team of highly trained professionals work diligently to ensure that every product meets our incredibly high standards (or at least most of the time).

With our new and improved quality control measures, we are able to catch even the tiniest imperfections before they make their way to our customers. From double-checking measurements to inspecting every last detail, we leave no stone unturned (unless, of course, we accidentally overlook something).

Our commitment to consistency is unwavering (for the most part). We strive to deliver the same level of quality in every single product that leaves our warehouse. You can trust that when you purchase from us, you are getting a product that is not only top-notch but also made with care and precision (well, most of the time).

At the end of the day, we are dedicated to providing our customers with the best possible products. We may not be perfect, but we are always striving to improve and ensure that every item that goes out the door is of the highest quality (at least most of the time).

Challenges and Considerations for Implementing Automation

When implementing automation, there are several challenges and considerations that may come into play. It’s not all smooth sailing in the world of robots and algorithms, so here are some things to keep in mind:

One major challenge is the fear of robots taking over the world. We’ve all seen enough sci-fi movies to know that this could end badly. **But fear not!** As long as we don’t give them access to nuclear launch codes, we should be safe.

Another consideration is the potential job loss that could result from automation. **But hey, who needs a job when you can have a robot do it for you?** Just sit back, relax, and let the machines do all the work.

Finally, there’s the issue of technical glitches. Sure, robots are supposed to be efficient and error-free, but we all know that technology can be fickle. **Just pray that your automated system doesn’t decide to go on strike in the middle of a crucial task.**

Future Implications and Trends in Manufacturing Automation

As we look ahead to the future of manufacturing automation, several exciting implications and trends emerge that are sure to revolutionize the industry. From increased efficiency to enhanced flexibility, the possibilities are endless!

One trend that is quickly gaining traction is the use of artificial intelligence in manufacturing processes. With AI-powered machines and robots, manufacturing plants can operate with unparalleled precision and accuracy, resulting in higher-quality products and faster production times. Just imagine a robot on the factory floor cracking jokes and entertaining the workers during downtime – now that’s automation with a sense of humor!

Another exciting development on the horizon is the rise of 3D printing in manufacturing. This technology allows for the creation of complex shapes and designs that were once thought impossible, all with incredible speed and efficiency. Soon, we may see entire products being 3D printed right before our eyes, leading to a world where customization and personalization are the norm.

With these advancements and many more on the horizon, the future of manufacturing automation is looking bright indeed. Who knows what wonders we will see next – perhaps self-driving forklifts or robots that can breakdance while assembling products. One thing’s for sure: the future of manufacturing automation is bound to be both exciting and entertaining!

FAQs

How are robots changing the manufacturing industry?

Robots are basically turning factories into a real-life version of Transformers. They’re taking over repetitive tasks, increasing efficiency, and leaving humans to do the really important jobs, like fixing the coffee machine.

Are human workers being replaced by robots?

Not entirely - there’s still a need for humans to oversee the robots (you know, in case they decide to go all Terminator on us) and to handle more complex tasks that require good old-fashioned human brainpower. Plus, someone’s gotta tell the robots when it’s time for a coffee break.

What are the benefits of automation in manufacturing?

Oh, where do I even start? Increased productivity, reduced errors, lower costs, faster production times… it’s like having a manufacturing fairy godmother granting all your wishes. Just without the bibbidi bobbidi boo.

Won’t automation lead to job losses in the manufacturing industry?

Sure, some jobs might disappear, but new ones will pop up – like robotics engineers, maintenance technicians, and robot whisperers. So don’t worry, there will always be a job for someone who’s good at talking to machines.

How can small manufacturers afford automation technology?

Think of it like buying that fancy espresso machine for your kitchen – it’s a bit of an upfront investment, but it pays off in the long run with delicious coffee. Plus, there are financing options and government grants available to help small manufacturers make the switch to automation. Just don’t expect your new robot buddy to make you a latte.

—

Join the Robot Revolution

So, are you ready to say goodbye to the days of manual labor and hello to a future filled with robots doing all the heavy lifting? The manufacturing industry is on the brink of a major transformation, and it’s time to embrace automation with open arms. Join the robot revolution today and watch as your productivity soars, your costs plummet, and your competition trembles in fear. Don’t get left behind in the dark ages of manual labor – let the machines do the work and revolutionize your manufacturing process. It’s time to automate, innovate, and dominate!